Pc Wire Stranding Production Line

Products Description

Advanced European technology is adopted for this Steel Wire Stranding line. The diameter range is 9.15mm - 21.6mm, and the highest speed of stranding can reach up to 120m/min. The new line has higher operation stability and longer service life. It's equipped with an advanced intelligent control system, which can realize the function of remote diagnosis, failure elimination, and maintenance reminder.

Products Parameter

|

Parameter |

Value |

|||

|

Control system |

PLC Bus-control |

|||

|

Max tension |

160000N |

|||

|

Speed |

65 - 120m/min |

|||

|

Range of diameter |

9.15 - 21.6mm |

|||

|

Speed adjusting |

AC VFD |

|||

|

Power |

650kw |

|||

|

Furnace |

600Kw, 380℃ |

|||

|

Tension pulley |

Φ2000 |

|||

|

Transmission |

Hard gear box |

|||

|

Spool |

Φ1250/Φ1120 |

|||

|

Coil size |

Φ760x750mm |

|||

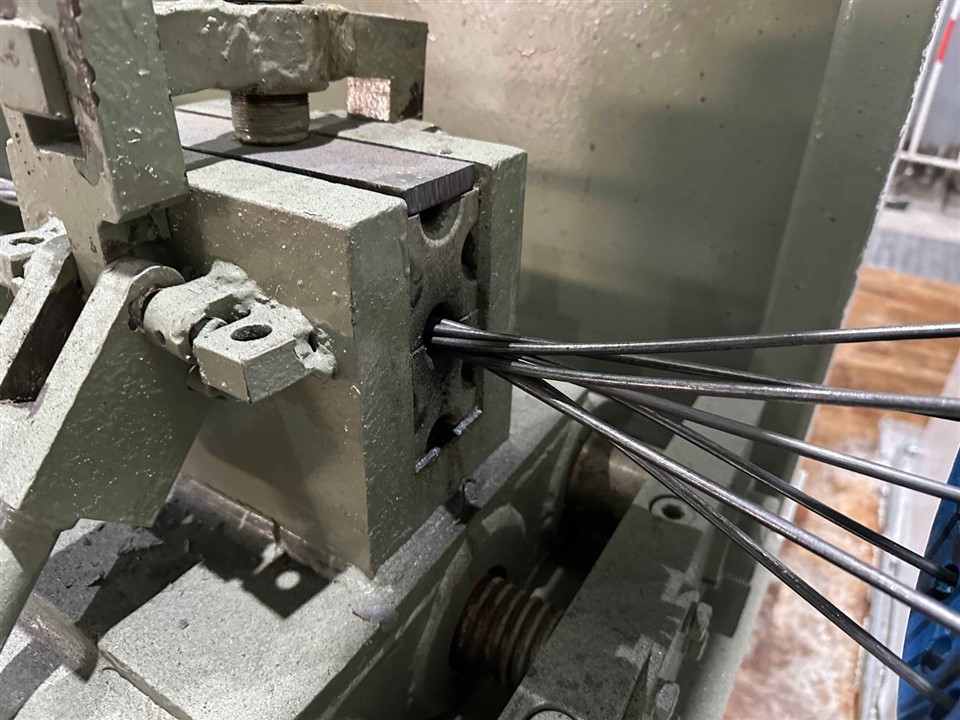

Products photos

pc wire stranding production line

Production Process Flow:

Pickling: High-carbon steel 82B wire rod is used as the raw material. After unpacking and loosening, it is immersed in a 10%-15% dilute hydrochloric acid solution for approximately 30 minutes at room temperature to remove surface impurities. After pickling, it is rinsed with water to remove residual acid.

Phosphating: The wire rod, after pickling and rinsing, enters the phosphating tank. A low-temperature, rapid phosphating process is used to form a phosphate chemical conversion film, i.e., a phosphating film, to improve the corrosion resistance of the substrate. No water rinsing is required after phosphating; the phosphating solution is simply drained off.

Saponification: The saponification solution is an aqueous solution of sodium soap. The wire rod undergoes saponification treatment to increase surface lubrication, preparing it for subsequent wire drawing. After saponification, no water rinsing is required; the saponification solution is drained before the wire enters the drawing process.

Wire Drawing and Stranding: A high-speed direct-draw wire drawing machine is used, employing a nine-stage cold drawing process to draw the wire rod in stages to the required diameter specifications. The finished wire is then fed into a stranding machine, where it is twisted and formed according to customer requirements, and then straightened by tensioning rollers.

Stabilization Treatment: The stranded wire is subjected to induction heating to improve its physical properties, increasing its strength and toughness, ultimately forming the steel strand.

Company Profile

Hebei Hylite Machinery Co., Ltd. is located in the center of the Beijing-Tianjin-Hebei economic & technological region - Xianxian Economic Development Zone, where is the birthplace of motto "Seeking Truth From Facts". The factory covers an area of 50 acres. We are engaged in the R&D, manufacturing and sale service of equipment for steel bar and metallic wire processing. *Has many years of rich experience in steel processing equipment, has a professional R & D team and after-sales service team based on Italian designers, the production of a variety of direct wire drawing machine, horizontal wire drawing machine, high-speed cold rolling ribbed steel equipment, steel stranding equipment, steel stranding equipment, PC steel rod equipment, welding wire equipment, steel stranding machine and other large and medium-sized steel processing equipment can be customized.

Hot Tags: pc wire stranding production line, China pc wire stranding production line manufacturers, suppliers, factory

Previous

No InformationYou Might Also Like

Send Inquiry