Nail Making Machine

Why Choose Us

Hebei Hylite Machinery Co., Ltd. is located in the center of the Beijing-Tianjin-Hebei economic & technological region - Xianxian Economic Development Zone, where is the birthplace of motto "Seeking Truth From Facts".

Products Sell Well

Our products have been exported to more than 60 countries including Togo, South Korea, Vietnam, Cambodia, Thailand, Malaysia, Philippines, Indonesia, India, Pakistan, Iran, Saudi Arabia, Russia, Egypt, Senegal, Mali, Benin, Niger, Venezuela, Argentina, Algeria, Mozambique, Mauritius etc.

Professional Team

The factory covers an area of 50 acres. We are engaged in the R&D, manufacturing and sale service of equipment for steel bar and metallic wire processing. The R&D team mainly composed of Chinese and Italian designers. It has a professional global after-sales service team.

Quality Assurance

The company has passed ISO9001 quality management system and got its CE certification. It is a certified high-tech enterprise in Hebei Province, China.

After-Sales Service

Provide customers with a full range of technical services and support, provide customers with on-site installation guidance free of charge, and train personnel to familiarize themselves with the operation and use of the equipment. If there are quality abnormalities in the equipment, we will provide 24-hour after-sales service to customers.

What is Nail Making Machine

Nail Making Machine is a continuous Nail Manufacturing process where in the Galvanized Wire passed Into Machine Mould and Nail Cutter Then Hammer Can shape in Nail Head and finished nail can automatically drop down. If you want to know the specifications and prices of Nail Making Machine, please contact us!

Advantages of Nail Making Machine

Lower Investment Risks

Opening any manufacturing facility requires significant upfront capital expenditure. However, nail production involves relatively less financial risk than many other industries.

That's because the primary raw material is steel wire, which has intrinsic value. If faced with declining nail orders, companies can sell off excess steel inventory to recover much of the initial investment.

Nail making machines themselves also retain substantial resale value after a few years of depreciation. So owners face less uncertainty if they decide to exit the market or switch production lines.

Flexible Production Scalability

Nail making machines enable companies to adjust outputs based on real-time demand trends. Owners can operate profitably with small urban factories or large rural production plants.

The modular nature of automated nail production lines allows for scaling. Companies can add machines incrementally to match supply with orders. This flexibility ensures optimum utilization of capital investments in the machines.

Seasonal demand surges, new client contracts, and overseas export orders can be readily fulfilled without major overhauls. This protects the balance sheet from extended lead times or large-batch nail inventory build-ups.

Recycling Steel Scrap for Environmental Gains

Nail making machines promote sustainability through recycling steel scrap as the raw material input. This includes reuse of discarded steel bars, sheet metal cuts, filings, and other residuals.

Turning trash into resource inputs cuts waste generation while meeting nail quality standards. Closed-loop steel recycling also drastically lowers carbon emissions associated with metal production.

So enterprises can derive triple benefits – environmental stewardship, material cost savings, and new revenues out of scrap resources. With increasing adoption of ESG frameworks globally, nail production via recycling offers green credentials.

Reliable Cash Flows and Profit Potential

Nail manufacturing serves as a steady avenue for earning revenues since nails have year-round market demand. With efficient machines, companies can ensure timely supplies even for bulk orders or customized nail designs.

Gross margins in nail production can hit 30-50% levels, translating into sound profitability. And by utilizing scrap metals and saving on manual labor, nail makers further boost their net earnings.

Over long periods, seasoned players in this sector remain insulated from severe demand shocks. They build loyal B2B customer bases comprising construction contractors, furniture makers, pallet manufacturers, etc.

Low-Maintenance Operations

Modern computerized nail making machines are designed for reliable, low-maintenance functioning. Built using quality components and advanced sensors, runtime failures are minimized.

Self-lubrication, automated voltage/frequency regulation, high-precision cutters, and dust shields enhance robustness while needing minimal manual supervision.diagnostics help detect emerging issues early.

When correctly operated per protocols and maintained proactively, nail making machines deliver years of consistent outputs. Preventive upkeep is far more cost-effective than unexpected breakdown repairs too.

Types of Products Produced By Nail Making Machines

Common Nail

Common nails are used for general construction and specifically for framing and other structural work.

Common nails have a thick shank, a wide head, and a diamond-shaped point. They are most commonly used with 2x dimensional lumber, such as two-by-fours. They are thick enough to be strong, but they are also more likely to split wood than thinner nails.

A special type of common nail is the sinker, with a slightly narrower shank and a special head designed to be sunk flush with the surface of the wood.

Box Nail

Box nails are similar to common nails and sinkers but have thinner shanks. They are better suited to thinner wood materials, such as 1x (3/4-inch-thick) lumber and exterior trim.

Box nails should not be used for structural projects because they lack the strength and holding power of common nails. The thinner shank of a box nail is less likely to split thinner materials.

Duplex Head Nail

Duplex head nails have two nail heads: one on top, and another slightly lower.

Duplex nails are used for temporary construction, such as formwork for pouring concrete or attaching temporary cleats during roofing. The nail is driven until the lower head is flush with the wood.

When it's time to disassemble the project, the nail can be extracted using the upper head and the claw of a hammer or pull bar.

Annular Ring or Ring Shank Nail

An annular ring nail, or ring shank nail, has rings on its shank for extra grip and additional resistance to pulling out of the wood.

These nails are commonly used for installing subflooring, where the extra holding power can help prevent floors from squeaking. Similar nails that may have rings include drywall nails or deck board nails, also for improved holding power.

Masonry Nail or Concrete Nail

Masonry nails and concrete nails are thick, short, and very strong. They are designed to be fastened into concrete, concrete block, and mortar joints, and are a staple of masonry work.

These nails are made of hardened steel, often with grooves along the length of the nail shaft to help them penetrate hard materials by spiraling as they are driven.

Finish Nail or Casing Nail

A finish or casing nail has a small, slightly rounded head slightly bigger than the nail shank. The head is designed to accept the pointed tip of a nail set, making it easier to countersink the nail without slipping.

A casing nail is essentially a large finishing nail. It is often used for installing exterior trim boards and nailing door frames and trim. Casing nails are commonly galvanized for corrosion resistance. The nail head is tapered and may be set flush or just below the wood surface.

Roofing Nail or Clout Nail

Roofing nails, sometimes called clout nails, have a short shank and a wide, flat, thin head.

Roofing nails are used to fasten shingles, roofing felt, or sheet metal to wood. The shanks can be smooth or ringed for increased pull-out resistance.

How to Choose Nail Making Machines

According to Your Own Budget

First of all, choose according to the budget. If the budget is sufficient and the machine is more than 20,000 US dollars, you can consider the high-speed nail making machine of new technology. If the budget is less than 10,000 US dollars, you can consider the traditional nail making machine.

Look at the difference between various nail making machines

The difference between high-speed nail making machine and traditional nail making machine. High-speed nail making machine is not only high-speed, high-capacity, but also stable and high-quality nails, low defect rate, reducing energy consumption and production costs. Help manufacturers to occupy a better position in the market more easily. The machine needs to look at the structure, speed, production, and defective rate. For example, the production capacity is less than 700pcs/h; the appearance of the structure is the big wheel on the side, it must be a traditional nail making machine. Because some manufacturers, in order to improve the grade and price of their own machines, also named their traditional nail-making machines as high-speed nail-making machines. This is just a marketing gimmick.

Understand the New Models

The most noteworthy thing for consumers here is that as long as it is a traditional nail making machine, it must not avoid the defects, that is, high energy consumption, high defect rate, high labor and production costs, although the machine is very cheap, only high-speed nail making The price is one-fifth of the machine, but the later use cost is relatively high, and the quality of the nails made is unstable, it is difficult to open the market well.

Our Factory

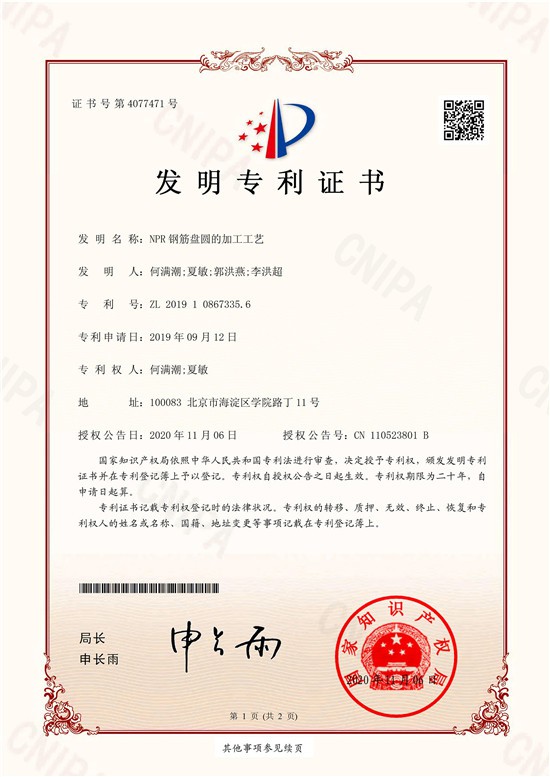

Certificate

Frequently Asked Questions

Hot Tags: nail making machine, China nail making machine manufacturers, suppliers, factory, BY Type Wire Straightener, Combined Wire Drawing Line, Sandblaster, Steel Bar Galvanizing Equipment, Other Machines, Tyre Bead Wire Machine

Previous

SandblasterYou Might Also Like

Send Inquiry