Sandblaster

Why Choose Us

Hebei Hylite Machinery Co., Ltd. is located in the center of the Beijing-Tianjin-Hebei economic & technological region - Xianxian Economic Development Zone, where is the birthplace of motto "Seeking Truth From Facts".

Products Sell Well

Our products have been exported to more than 60 countries including Togo, South Korea, Vietnam, Cambodia, Thailand, Malaysia, Philippines, Indonesia, India, Pakistan, Iran, Saudi Arabia, Russia, Egypt, Senegal, Mali, Benin, Niger, Venezuela, Argentina, Algeria, Mozambique, Mauritius etc.

Professional Team

The factory covers an area of 50 acres. We are engaged in the R&D, manufacturing and sale service of equipment for steel bar and metallic wire processing. The R&D team mainly composed of Chinese and Italian designers. It has a professional global after-sales service team.

Quality Assurance

The company has passed ISO9001 quality management system and got its CE certification. It is a certified high-tech enterprise in Hebei Province, China.

After-Sales Service

Provide customers with a full range of technical services and support, provide customers with on-site installation guidance free of charge, and train personnel to familiarize themselves with the operation and use of the equipment. If there are quality abnormalities in the equipment, we will provide 24-hour after-sales service to customers.

What is Sandblaster

Sandblasting equipment encompasses systems or machinery, along with components for projecting blast media onto a part's surface to abrade, clean, or modify it. Media such as sand, abrasives, metal shot, and other materials are propelled using pressurized water, compressed air, or a blast wheel. If you want to know the specifications and prices of Sandblaster, please contact us!

Advantages of Sandblaster

Effectively Prepares Metal Surfaces for Coating Application

The two main functions of coating are decoration and protection. A professional finish gives a product the appeal factor, especially the metal products. A paint job will be far more effective on a well-polished surface because of increased adhesion. The coating will not only last for long, but it will also protect the metal product, and increase its service life. When you scuff a metal surface, you get rid of impurities such as oil and rust that can affect the final quality of the coating. Sandblasting is great for both powder coating and liquid coating. If you manufacture metal products, it is best to seek these services before applying the final finish.

Quick

Sandblasting machines make the process easy and fast. One person can operate the sandblaster, and this reduces the labor costs. There is no need for intensive preparations that utilize harsh chemicals and extensive scrubbing when you choose to scuff. Additionally, after the sandblasting job is complete, cleaning up is easy. There isn't much waste to collect in the sandblasting booth, save for the sandblasting grit. Some of the sandblasting materials, such as glass beads, can be reused. If you had to manually scuff metal using sandpaper, it would take you more time to complete a project.

Safer and Less Wasteful

Most of the abrasive materials used in sandblasting, such as glass beads, are non-toxic. Most professional finishers utilize non-toxic materials because they are also recyclable. The only element of sandblasting that may harm people is the dust produced in the process. It may contain toxic-silica, which is a known cause of lung diseases. However, manufacturers utilize protective clothing that protects the workers from inhaling the toxic dust. Moreover, the whole sandblasting process takes place in a booth that is well ventilated.

Cost-effective

To scuff a surface, you only need a sandblaster and the abrasive materials. After setting up your sandblasting booth and buying the sandblasting machines and protective clothing, you will not have additional startup costs. The other cost-benefit is that most of the abrasive materials used in the process are recyclable and readily available. Compared to other alternatives such as laser cleaning, sandblasting is a big bargain for manufacturers. Additionally, sandblasting takes less time, and this allows manufacturers to work on more units.

Types of Sandblaster

Air or Dry Blast Equipment

Air abrasive blasting or dry blast equipment utilize compressed air to propel the blast media. Pneumatic or compressed air blast systems are generally categorized into two types: suction and direct pressure.

Suction or Siphon Blast Equipment

Suction blasters or blast cabinets employ the venturi siphon effect to such abrasive into a pressurized stream of fluid, air, or water.

Venturi devices use a constriction in a moving fluid stream to create a pressure differential or vacuum. This causes the blast media to be drawn into the air or water stream at the point of constriction.

Venturi devices are used across various industries. They are employed to create a vacuum for mechanical holding applications, while ejectors and eductors move fluids, powders, or solids in chemical processing industries.

Suction blast cabinets or portable siphon blasting pots are generally less expensive than pressure blast systems. Economy blasters often use suction mechanisms and do not require a pressure vessel, consuming only half the pressurized air compared to pressure blast cabinets. However, suction blasters need higher air pressure to maintain media flow.

Direct Pressure or Pressure Blast Equipment

Pressure or direct pressure abrasive blast equipment makes use of a pressure vessel to energize the abrasive media. A pop-up or metering valve on the pressure vessel is opened to release pressurized fluid and blast media into a blast hose. The pressurized media travels through the blast hose to the direct pressure cabinet and blast gun.

The Basic Idea

While there are three different types of sandblasters that you can choose from for your needs, all of these media blasters have the same general method in common. Media blasting is done by an air-powered gun which will propel silica sand toward a surface at a high rate of speed. Compressed air is used to supply the power to the gun, and the sand is forced out of a barrel which will direct it toward your target. Obviously, this process can be dangerous when not done in the right setting, so precautions should always be taken before getting started.

Gravity-Fed

The first type of blaster to consider is a gravity-fed gun. As the name would suggest, the sand is directed into the barrel of the gun from the top, thanks to gravity. There is a hopper on top of the gun which holds your supply of sand as you work. When the trigger is pulled, sand will be forced out of the barrel, and more sand will fall from the hopper into the barrel to continue the process. When the trigger of the gun is released, the opening between the hopper and the barrel will close to keep the remaining sand inside of the hopper for future use.

Pressure Blaster

An alternative form of sand delivery to the barrel of your gun is through the use of a pressure blaster. In this case, there is a canister containing sand which is already under pressure. When that canister is connected to a gun via a specialized hose, the trigger can be pulled and the sand and air will come out of the canister together. You will not experience hardly any maintenance needs when opting for this style of sandblaster, but the cost of operation tends to be higher. Also, you cannot refill the canister once it has been exhausted, meaning there is more waste created with this method.

Siphon Sandblaster

For the last option, suction is going to be the main source of the action within the siphon sandblaster. In this case, a gun is connected via two hoses to both an air compressor and a sand reservoir of some kind. When the air kicks on, it will create suction through the gun which will pull the sand through and out the barrel. This type of operation is relatively affordable, and it can be used continuously as the sand can simply be recollected and placed back into the reservoir. When a large surface needs to be stripped clean, it is usually a siphon media blaster that will be put into action.

Wet Abrasive Blast Equipment

Water can be used instead of air to propel the blast media. Wet abrasive blasting or water blasting can reduce dust generated during abrasive blasting by over 90%, which is crucial when stripping or cleaning parts containing heavy metals and hazardous materials.

An interesting aspect of water blast equipment is its ability to offer additional surface modification through water additives. Chemicals can be included to break down hard-to-remove films or grease, and anti-rust agents can be added to protect the parts until coatings are applied.

Although some suppliers refer to wet abrasive blasters as dustless blast equipment, no blasting system eliminates 100% of dust.

Water blasting can keep parts cooler compared to dry blasting, which helps reduce warping or distortion in thin sections. It is also advantageous for handling explosive dust, such as aluminum or titanium dust, as wet blasting suppresses static discharges and ignition risks.

Applications of Sandblaster

Strips Off Paint and Corrosion

This is the primary task of sandblasting. It is a common knowledge that paint and corrosion marks are hard to get rid if you just rely on conventional cleaning techniques.

The reliable sandblasters can eliminate stubborn paint and rust plus other contaminants from cars, houses, machines, and other surfaces. With regards to removing paint from cars, the process is mild enough to strip off the paint without harming the metal underneath.

Cleans Smaller Tools

You may be surprised, but sandblast cleaning is not confined to enormous machines and buildings. This vital process can also be relied on to clean smaller instruments like automobile and metal tools. Examples of these are rusty screwdrivers and wrenches which can be quickly cleaned by sandblasting.

Meanwhile, you can sandblast machinery clogged with oil, dirt, and grease to ensure efficient functioning. Besides that, the cleaning process prevents machine breakdown and wear and tear.

Smooths and Polishes Devices

While cleaning is the main function of sandblasting, the process also leaves surfaces shiny and polished. In some occasions, you will find small mechanical parts made out of metal and plastic featuring rough burrs or other irregularities which make it impossible to assemble.

Not only does sandblasting polishes surfaces but it also removes burrs, tags, and excess material to guarantee productive assembly. Moreover, it smooths edges to attain the intended shape of the surface.

Creates Impressive Art

Yet, another surprising application of sandblasting is to create impressive art and designs. Talented artisans use the technique to carve remarkable patterns on different surfaces such as wood, metal, glass, and other materials.

Aside from this, other artists use the method to improve the aesthetic value of lackluster commercial properties.

Cleans Concrete Surfaces

More than its industrial and mechanical purpose, the sandblasting process is a viable method to clean streets, walkways, pavements, and other concrete surfaces. With these areas ordinarily neglected, routinely cleaning and maintaining them extend their lives and minimize the possibility of accidents.

Without wasting water, you can effectively and quickly scrub clean concretes and pavements with sandblasting by using high-speed abrasives.

Prepares Surface for Coating Activity

After sandblast cleaning, your surface is now prepared for painting, bonding, or some other coating activity. Substandard surface preparation will eventually lead to a failed coating system. Achieving a marginal level of cleanliness that leaves behind contaminants in the area will subsequently reduce the coating service life.

Having said that, sandblasting is an effective process for surface preparation. Inability to sufficiently prepare your surface for coating will only result to waste of money. Incidentally, fragile surfaces like wood may be cleaned with gentler media such as walnut shells or glass beads.

Restores Authentic Image of Bricks And Stones

Bricks, stones, and concrete are ordinary raw materials used for residential and commercial properties. While painting is an option to improve the appearance of a deteriorating building or structure, sandblasting is a smarter solution to remove unnecessary mortar, cement, paint, and other substances.

Not only does it restore the original condition of the material but it also increases the longevity of the property.

Enables Mold Remediation

Mold is a prevalent problem found in homes. Lots of health issues caused by mold are already documented if it is not properly addressed. Concerns including itchy eyes, coughing, sneezing, asthma attacks, severe allergic reactions are some of the consequences of this problem. Take note though, implications can also be dangerous such as permanent lung damage.

Nowadays sandblasting is a new technique to eliminate mold. Medium used for the process is either baking soda or dry-ice. One of the benefits of this method is that the places which are usually tough to access like attics and crawl spaces are now easy to clean. Aside from that, sandblasting provides for the quick and effective elimination of mold with minimal damage and clean-up.

Creating Etched Signs

As mentioned earlier, sandblasting can be used for smaller projects. This handy process can also be utilized for spectacular signs from wood, glass, or stone. Memorials are a practical sample of this nifty sandblasting technique.

The advantage of using this method is that it has more depth than laser engraving. Having more depth means you can add color to your project to highlight your design. A lot of businesses use this technique to artistically showcase their logo or business name.

Our Factory

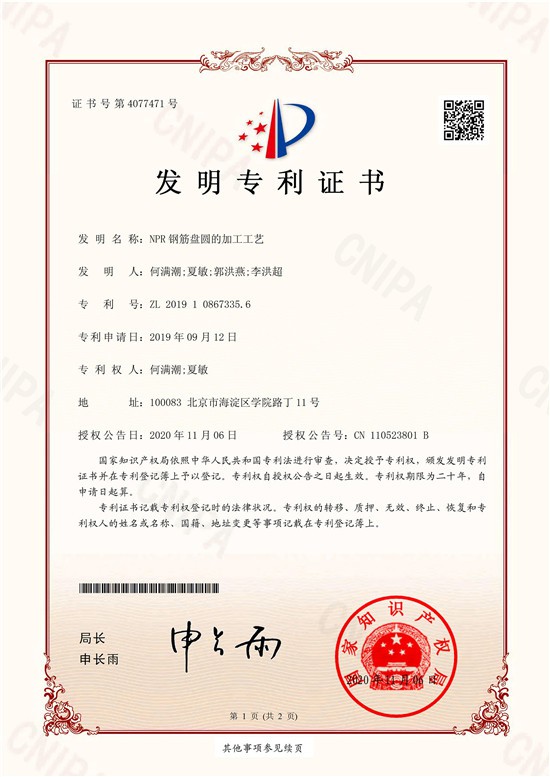

Certificate

Frequently Asked Questions

Hot Tags: sandblaster, China sandblaster manufacturers, suppliers, factory, Tyre Bead Wire Machine, Spring Steel Wire Drawing Machine, Combined Wire Drawing Line, Cold rolled Ribbed Steel Bar Machine, BY Type Wire Straightener, Steel Bar Galvanizing Equipment

Previous

Spool Take-up UnitYou Might Also Like

Send Inquiry